As Completion Engineers, we leverage advanced engineering software and modeling tools to design, optimize, and execute well completions that maximize production, ensure long-term integrity, and minimize operational risks.

How We Apply Technologies to Deliver the Best Solutions

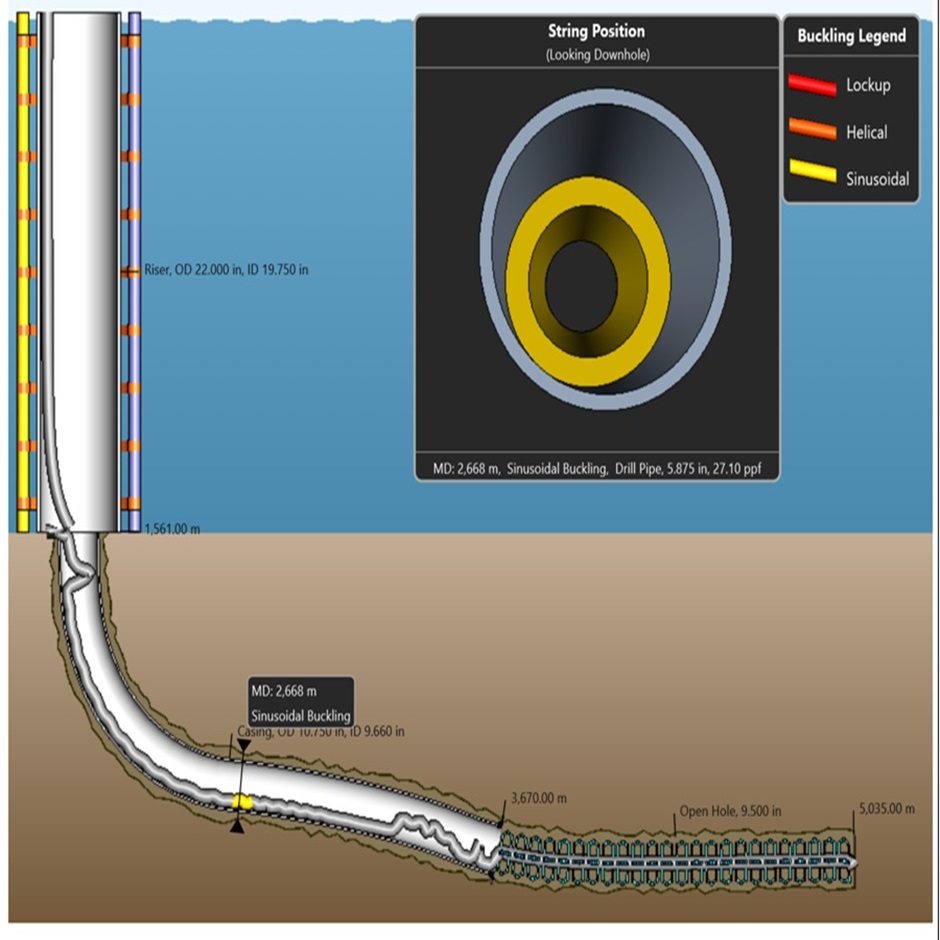

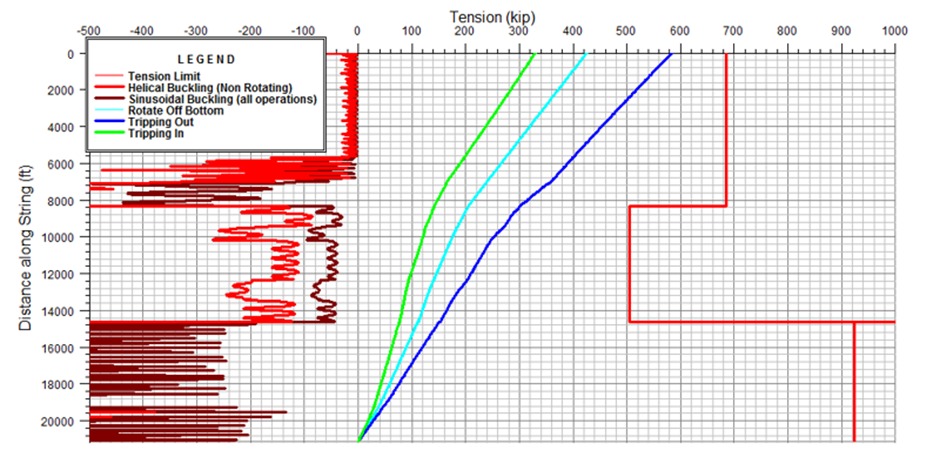

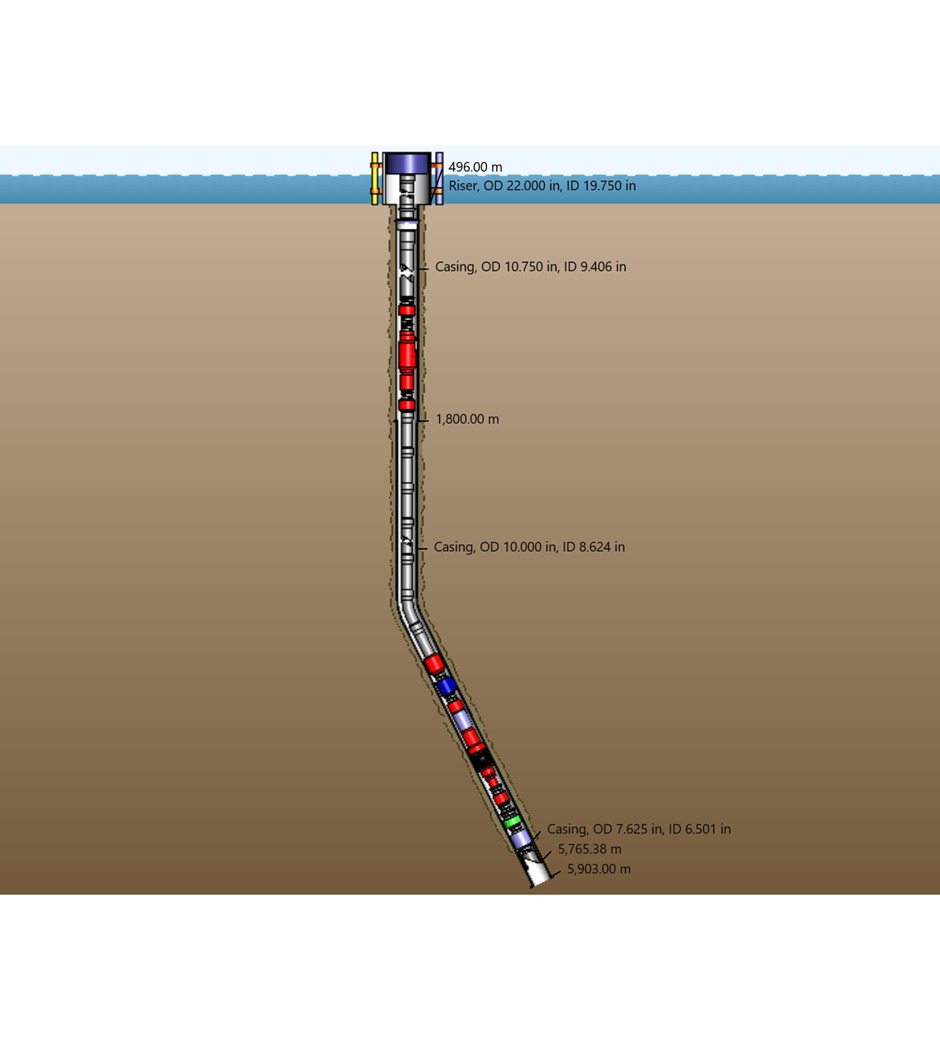

We use casing and tubing stress analysis tools to ensure mechanical integrity under downhole conditions. Nodal analysis and well performance modeling help us evaluate different completion scenarios, optimizing production rates before implementation.

For unconventional reservoirs, we employ fracture propagation modeling to optimize cluster spacing, proppant placement, and fluid systems. Pressure-matching techniques validate fracture geometry, while reservoir simulators predict long-term production impacts.

In sand-prone wells, we apply gravel pack and screen modeling tools to prevent sand ingress while maintaining flow efficiency. Cementing and zonal isolation simulations ensure proper barrier placement to avoid fluid migration.

We optimize perforation density, phasing, and charge selection using advanced gun design software, enhancing connectivity between the wellbore and reservoir while minimizing near-wellbore damage.

We model ESP, gas lift, and rod pump systems to select the most efficient artificial lift method. Flow assurance analysis helps mitigate issues like slugging and liquid loading, sustaining long-term production.

Through finite element analysis (FEA), we assess casing and completion durability under extreme loads. Tubing movement simulations in HPHT wells prevent costly failures, ensuring long-term reliability.

We use production analytics platforms to identify underperforming wells for re-stimulation. Execution tracking tools improve operational efficiency, while cloud-based collaboration systems enable real-time decision-making with clients.

Stress regime analysis ensures fractures stay within target zones, preventing unwanted height growth. Discrete fracture network modeling helps optimize stimulation designs for better recovery.

Post-completion, cleanup efficiency modeling ensures effective stimulation, while flowback diagnostics validate fracture performance and guide future designs.

By combining geological and well log data with completion designs, we ensure perforations and fractures target the most productive zones, maximizing reservoir contact.