At BESL, we provide comprehensive well intervention engineering solutions to optimize production, restore well integrity, and extend asset life. Our expertise covers the full spectrum of intervention operations—from diagnostics to execution—ensuring safety, efficiency, and cost-effectiveness for your wells.

Our Well Intervention Engineering Services

- Casing/Tubing Inspection: Advanced electromagnetic (EMI) and ultrasonic (USIT) logging to detect corrosion, leaks, and mechanical damage

- Cement Evaluation: Cement bond logs (CBL/VDL) and barrier verification for P&A or remediation.

- Pressure & Leak Testing: Confirm wellbore integrity before intervention.

- Production Logging (PLT): Identify water/gas breakthrough, poor zonal contribution, or mechanical issues.

- Reservoir Performance Analysis: Pressure transient testing and inflow profiling to optimize production.

- Tracer & Temperature Surveys: Locate fluid entry points and cross-flows.

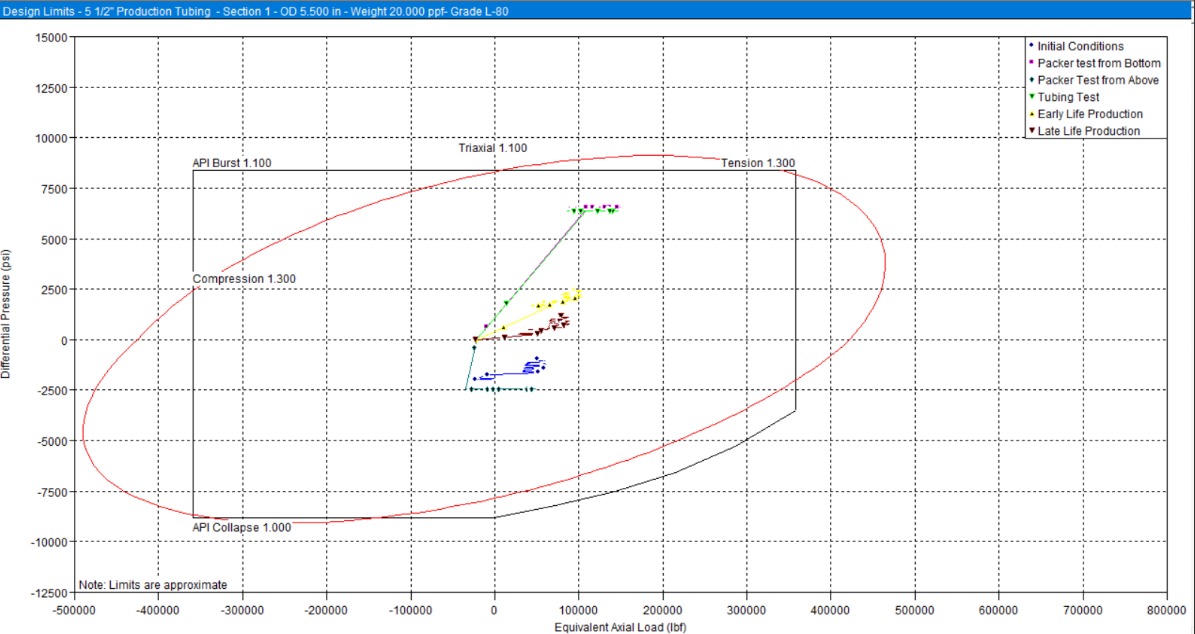

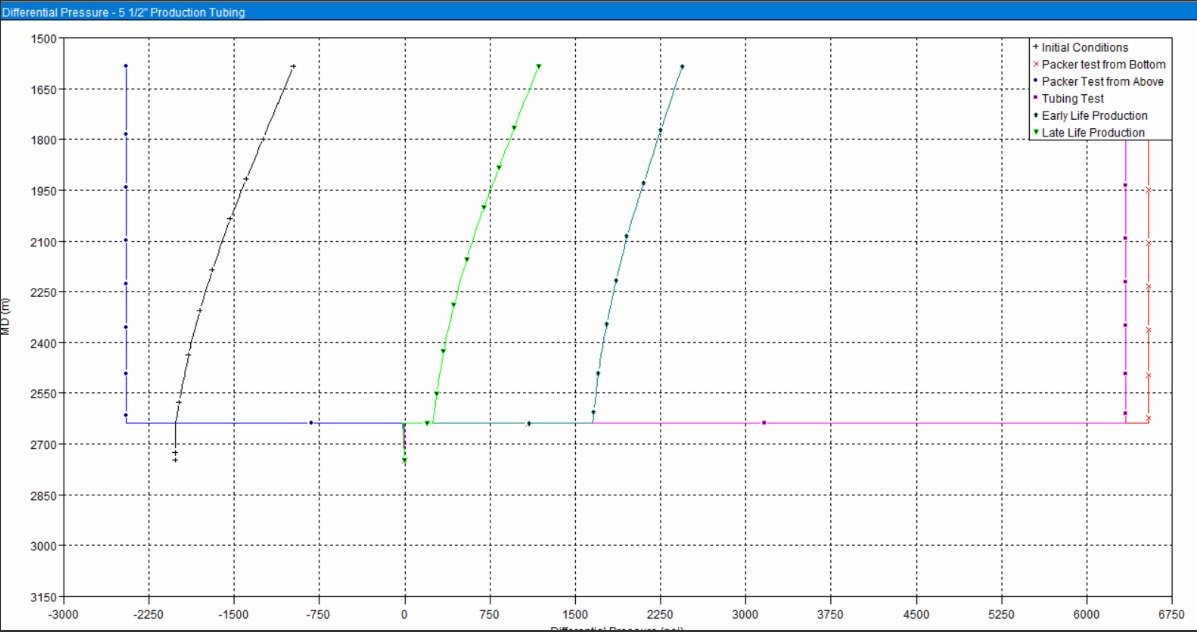

- Feasibility Studies: Assess rigless intervention viability (load analysis, kill fluid design).

- BOP & Lubricator Design: Ensure compliance with well control standards.

- Execution Planning: Risk assessments and contingency procedures.

- Job Modeling: Simulate forces, lockup, and reach for cleanout, perforating, or stimulation.

- Fluid & Chemical Selection: Non-damaging fluids for sand cleanout or acidizing.

- Fishing & Stuck Tool Recovery: Jarring analysis and retrieval strategies.

- Re-Perforation Design: Optimize phasing, density, and charge type for maximum inflow.

- Acidizing/Fracturing: Custom designs for matrix stimulation or frac re-entries.

- Sand Management: Gravel pack redesign, resin consolidation, or mechanical solutions.

- Riserless Feasibility: Thermal and hydrate risk assessment.

- ROV & Subsea BOP Analysis: Operability limits for subsea stack deployment.

- Dual Gradient & Managed Pressure Interventions: Specialized kill fluid designs.

- Cement Plug Design: Length, compressive strength, and placement verification.

- Barrier Testing & Verification: Logging and pressure testing for regulatory compliance.

- Cut & Pull Simulations: Casing removal analysis for slot recovery.